Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do I calculate all these values and what criteria are important when choosing the right operating clearance? Perhaps you are confronted with such questions – you will find the answers and more detailed information in this article.

Definition of bearing clearance and operating clearance

The bearing clearance refers to an uninstalled rolling bearing and can be described as the internal mobility of the rolling elements and the rings in both axial and radial directions. The operating clearance can also be described as the internal mobility of the rolling elements and the rings in both directions, but it refers to an installed bearing in operation.

Internal clearance

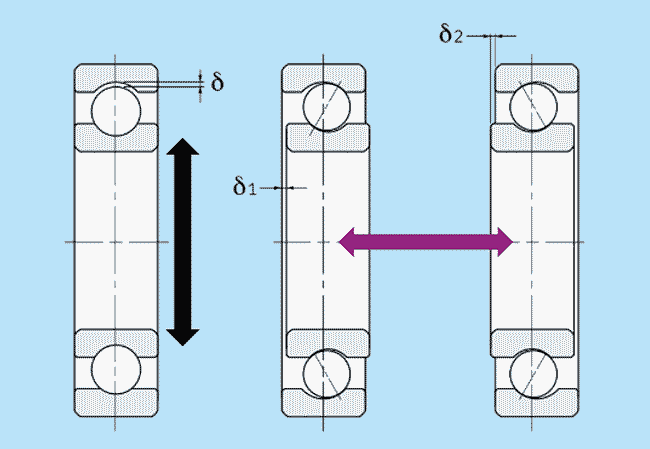

The most practical way to explain internal clearance is to imagine a bearing (for example, a deep groove ball bearing) that you are holding in your hand. If you try to move the inner ring of this bearing up and down or to the left and right while holding the outer ring, you will notice a small displacement in the radial (black arrow) or axial direction (purple arrow). This displacement is called bearing clearance. Conversely, the inner ring can also be held and the outer ring moved up and down or to the left and right. This is also referred to as bearing clearance.

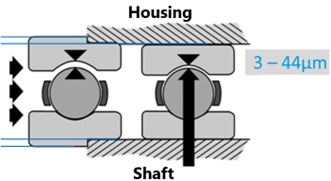

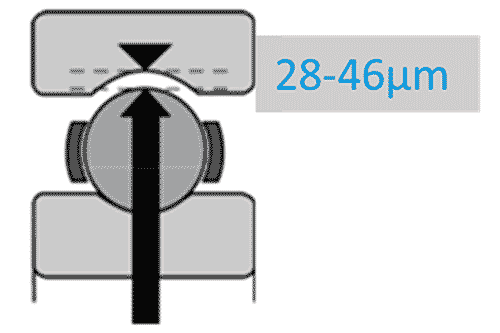

But enough theory. What about the bearing clearance in a practical example? For a bearing 6008C4, for example, the radial internal clearance is 28-46µm (= C4). In the first step, bearing 6008C4 is mounted once on a steel shaft that has, for example, a k6 tolerance (+2 -> +18µm). Since bearing 6008C4 has a tolerance on the inner ring of 0/-12µm the resulting fit between the inner ring and the shaft gives 2 to 30 microns of interference. This value is obtained by looking at the tolerances on the bearing inner ring and the shaft.

Only extreme values are taken into account, which cover the range when the “largest” bearing is mounted on the “smallest” shaft or the “smallest” bearing is mounted on the “largest” shaft. In this example, this would be the following cases:

- Shaft with 40.002 mm outside diameter (OD) and bearing with 40.000 mm inside diameter (ID) = 2 µm interference

- Shaft with 40.018 mm OD and bearing with 39.988 mm ID = 30 µm interference

Some force is needed to mount the 6008C4 on the shaft to overcome the interference. Due to this interference, the bearing clearance is reduced so that after mounting on the shaft it becomes +3µm -> +44µm. Now the shaft is mounted with the 6008C4 inside a steel housing. In this example, the housing has a H6 (0µm/+19µm) tolerance and the outer ring of the bearing has a tolerance of 0/-13µm.

Comparable to the shaft, the housing bearing fit and outer ring tolerance are considered. Here, the following applies:

- Housing with 68.000 mm inside diameter (ID) and bearing with 68.000 mm outer diameter (OD) = 0 µm

- Housing with 68.019 mm ID and bearing with 67.987 mm OD = 32 µm

As you can see, the resulting fit between the outer ring and the housing is a clearance of 0µm – 32µm. This does not change the clearance in the bearing: +3 -> +44µm.

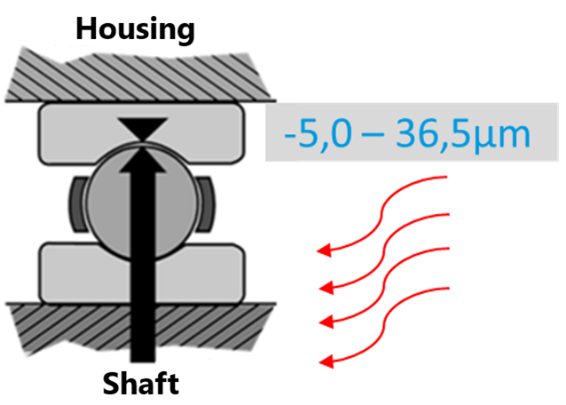

The shaft is then rotated at 8,000 rpm, for example. The bearing 6008C4 now has a temperature of 100°C on the inner ring and 90°C on the outer ring. But what is actually happening now? Well, the inner ring and the outer ring expand due to the heat, but the inner ring expands more than the outer ring due to the temperature difference. Because of this, the clearance in the bearing is reduced from +3 -> +44µm to -5.0 -> +36.5µm. This reduction of about 7.5µm is calculated with a computer programme or alternatively with the help of catalogue formulas.

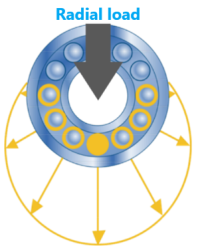

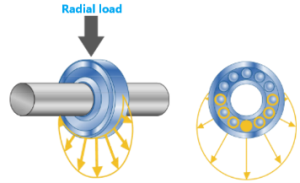

If a radial force is now added, this increases the radial internal clearance again. The reason for this is that some of the rolling elements absorb the radial load while the other rolling elements are relieved. The rolling elements under load will deform slightly (elastic deformation). In the illustration of radial load, this is shown for a deep groove ball bearing. The length of the yellow arrows indicate the magnitude of the force acting on the rolling elements where the elastic deformation is proportional to the force.

There are different groups of radial internal clearance for rolling bearings. These can be seen in the table. (Note: The axial internal clearance can be calculated from the radial clearance using formulae, for example for deep groove ball bearings).

| Internal clearance | Meaning | Possible applications |

| C2 | Bearing clearance is smaller than normal |

|

| CN | Standard bearing clearance |

|

| C3 | Bearing clearance is larger than normal |

|

| C4 | Greater than C3 |

|

| C5 | Greater than C4 |

|

You will certainly not come across CN, C3 and C4 for the last time. The other bearing clearance classes are only used under special operating conditions.

Operating clearance

We can now say that the bearing clearance in the operating state is -5.0µm to 36.5µm. This bearing clearance during operation is also called operating clearance. The corresponding changes to the bearing clearance depending on the assembly condition can be seen in the table.

| Summarised results | ||||||

| Step | State | Radial internal clearance/operating clearance | ||||

| 1 | Before assembly | 28µm – 46µm | ||||

| 2 |

After assembly on the shaft (k6 tolerance) |

3µm – 44µm | ||||

| 3 |

After assembly into the housing (H6 tolerance) |

3µm – 44µm | ||||

| 4 |

In operation, 8,000rpm, Inner ring temperature: 100°C, Outer ring temperature: 90°C |

-5.0µm – 36.5µm | ||||

| 5 | Radial force of 1,000 N | +7,3µm -> +48,7µm | ||||

This table summarises the most important factors affecting radial clearance.

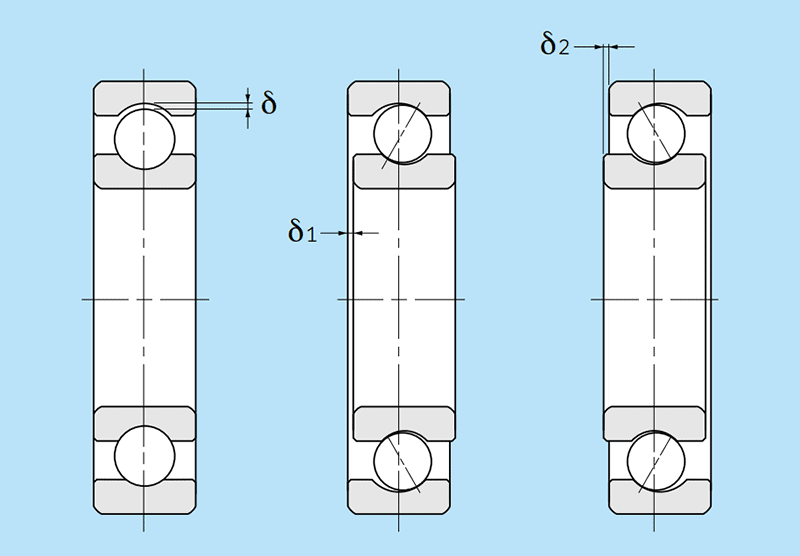

Formula 11

Radial clearance = δ

Axial clearance = δ1+δ2

The determination of radial and axial clearance.

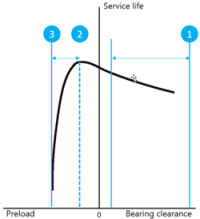

Example: Relationship between operating clearance and service life

A targeted and careful selection of the bearing clearance is elementary, as the subsequent operating clearance has an effect on the service life (not the L10h service life), the temperature curve, the bearing performance as well as the running noise. The effects of the operating clearance on the service life are shown in the graph.

As you can see in the figure, the life span drops rapidly in areas 3 and 1. But why does the service life decrease so much? Let’s assume that the bearing 6008C4 mentioned in the example above has 12 balls (rolling elements). However, if the temperature difference between the inner ring and the outer ring now always increases, the operating clearance will continue to decrease (range 3). As a result, all 12 rolling elements are now in contact, increasing resistance to rotation until eventually sliding occurs (rolling no longer takes place). This reduces the service life to the point of total failure!

If the table for the bearing clearance classes mentioned above is extended by a further column, the balls which “bear” the radial force (for example the weight of the shaft) are shown in the fourth column (load bearing).

| Step | State | Bearing clearance/ Operating clearance | Load bearing balls | Service life area (see graph above) | Note | ||||||

| 1 | Before assembly | 28µm – 46µm | – | – | – | ||||||

| 2 | After assembly on the shaft (k6 fit) | 3µm – 44µm | 3 – 12 | 1–2 | – | ||||||

| 3 | After assembly into the housing (H6) | 3µm – 44µm | 3 – 12 | 1–2 | – | ||||||

| 4 | In operation, 8,000rpm, Inner ring temperature: 100°C, outer ring temperature: 90°C | -5,0µm – 36,5µm | 12 – 12 | 2–3 |  The bearing 6008C4 has an inner ring temperature of 100°C and outer ring temperature of 90°C at n= 8,000rpm. | ||||||

| 5 | Radial force of 1,000 N | +7,3µm -> +48,7µm | 7 – 12 | 2–1 |  Bearing 6008C4 is in operation with a radial load of 1,000N. | ||||||

This table shows how many balls or rolling elements bear the load depending on the operating clearance.

The calculation of the operating clearance

Even though the operating clearance should (theoretically) ideally be slightly negative in order to achieve maximum bearing life, in practical everyday life under normal operating conditions, operating clearance is usually targeted at just above zero. The reason for this is that this negative operating clearance (preload) could increase if a rolling bearing is exposed to changing operating conditions. This would in turn lead to the reduction in service life already described.

To calculate the operating clearance, factors such as fits as well as temperature differences that occur between the inner and outer ring must be taken into account.

Formula 12

δeff = δo – ( δf + δt )

δeff = Effective interference (due to fits), mm

δo = Bearing clearance, mm

δf = Decrease in bearing clearance due to interference caused by fits, mm

δt = Decrease in bearing clearance due to temperature differences between inner and outer rings, mm

The calculation of the operating clearance δeff requires three variables.

The interference δf

The bearing clearance is reduced due to interference δf between the inner ring and shaft or outer ring and housing. Due to the interference δf between the inner ring and the shaft, the inner ring expands or the outer ring contracts (interference between the outer ring and the housing) during mounting.

Formula 13 can be used to calculate the reduction in bearing clearance. For the sake of simplicity, factors such as the shape of the bearing, shaft and housing as well as the materials used are taken into account by a numerical value of 70%-90%. In general, the larger the interference, the more the bearing clearance is reduced.

Formula 13

δf = (0,70 ~ 0,90) ∆deff

∆deff denotes the effective interference in mm.

The temperature difference δt

The calculation of the value δf is not the whole picture. The next step is to calculate the variable δt which takes into account the reduction of the operating clearance due to a temperature difference in the bearing. An important piece of information: When the bearing is in operation, the outer ring is typically 5 to 10°C cooler than the inner ring, for example. Under certain conditions, such as above-average heat dissipation of the housing, this difference can be even greater.

Formula 14

δt= ∝×∆T×Do

∝= Temperature coefficient of expansion of the bearing material, 12,5× ((10)*6/℃)

∆T= Temperature difference (inner/outer ring) in °C

Do= Outer ring raceway diameter, mm

When calculating the reduction in operating clearance due to a temperature difference, you must take several factors into account.

The raceway diameter of the outer ring Do

In order to determine the raceway diameter of the outer ring again Do (approximately), one must use formula 15 or formula 16, depending on the type of rolling bearing.

Formula 15

For ball bearings and spherical roller bearings:

Do = 0,20 (d+4,0D)

Formula 16

For roller bearings (except spherical roller bearings):

Do = 0,25 (d+3,0D)

The calculation of the raceway diameter of the outer ring Do is different for ball bearings and roller bearings.

Preload

So far, this article has been about bearing clearance classes and how they change during operation. But depending on the application, it may be necessary to preload bearings axially.

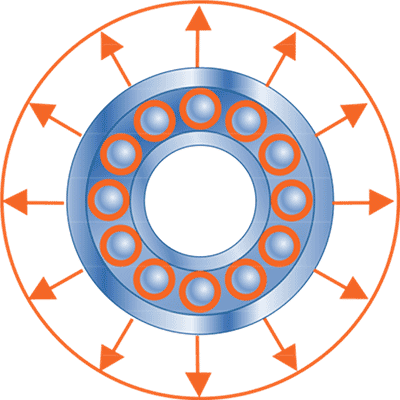

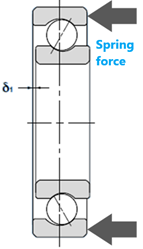

One possibility, which is often used in electric motors, for example, is axial preloading of the rolling bearings by means of a spring (preloading by means of a constant sprung preload force). This is shown symbolically in the illustration. The spring force acts around the entire circumference.

Why is this done? The spring preload force causes all the balls to fit snugly against the raceways of the deep groove ball bearing (axial bearing clearance = 0µm). The preload thus causes a tension at the contact points of rolling elements and raceways. This reduces the operating noise and improves the vibration behaviour.

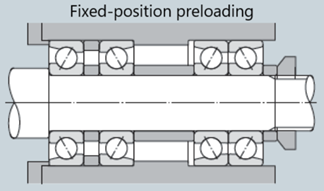

Another application is the bearings in a machine tool spindle (hence the name spindle bearing). Here, the spindle bearings are axially preloaded either by means of a spring, as with the electric motor, or alternatively via a fixed–position clamping system.

Preload is most likely to occur in angular contact ball bearings and tapered roller bearings, and a slight preload also has a positive effect on the overall service life. In the context of preload, one should always consider the purpose and the goal, because preload also carries risks, especially if preload is excessive. Therefore, it shouldn’t be overlooked that this can lead to increased surface pressure, extremely high heat generation and a shortening of the bearing service life.

Effects of preload:

- Increase in rigidity

- Only conditionally recommended for highest speeds (applies to fixed-position preload)

- Concentricity and positioning accuracy are improved

- Positive influence on vibrations and running noise

- Lower risk of skidding

Forced guidance of rolling elements on the guide rib (for example with tapered roller bearings)

Preload has several effects.

You may also be interested in

Fit selection

Interference fit, transition fit, clearance fit. You should know and be able to define these three types of fit after reading this article. But before

Lifetime calculation

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

Materials and manufacturing

Materials and manufacturing Have you already had a look at our chapter on structure and function? Maybe you asked yourself what rolling bearings are actually

O, X and tandem arrangement

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different

The angular contact ball bearing

The angular contact ball bearing is virtually the brother of the deep groove ball bearing. Characteristics of angular contact ball bearings Perhaps you already know

The tapered roller bearing

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the