We have learned about standard bearing units which are only suitable for bearings with a spherical outer surface. As a rule, these bearing units cannot accommodate rolling bearings with a cylindrical outer ring surface.

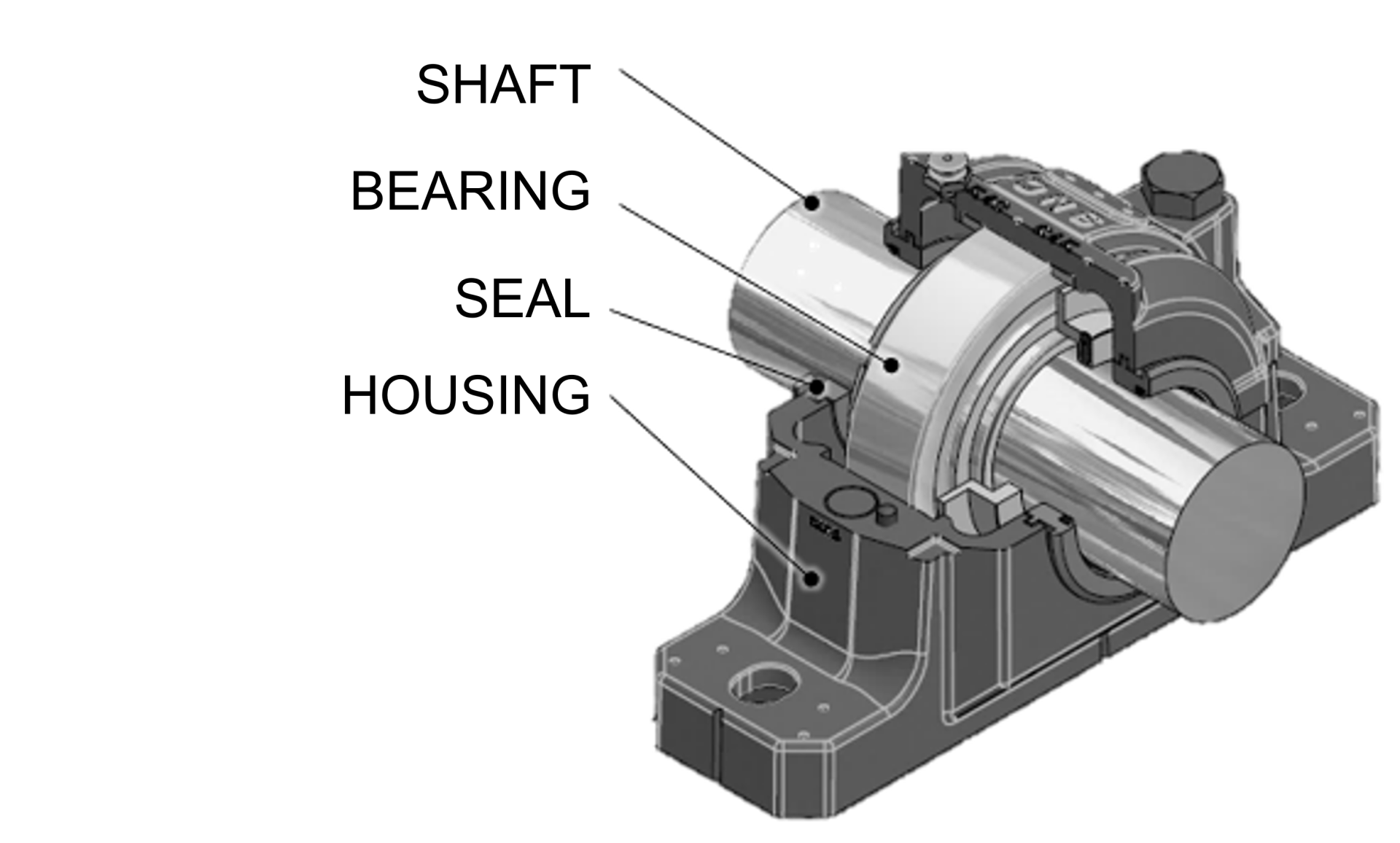

Bearing housings, on the other hand, are equipped with cylindrical bearing seating surfaces and can accommodate standard rolling bearings of various types. They can be differentiated on the basis of their design and construction. Possible designs include plummer block housings, flanged bearing housings and other special bearing housings. Plummer block housings are also available with a split or one-piece housing body. Bearing housings are suitable for industrial use in a wide range of applications and machines. The right choice of bearing housing depends on the application purpose and the expected requirements in operation.

Split designs

In the split design, the upper part of the housing and the lower part of the housing can be dismantled, making it easier to mount the bearing and other components from above. Split plummer block housings are designed to accommodate a rolling bearing. This type of housing is represented in many areas of industry.

The SNC series from NTN can be described as a real all-rounder, as it can be adapted to the application in the best possible way by using different rolling bearings and seales.

Features of split versions of the SNC series:

- Simple Assembly

- Modular system

- High efficiency and economy

- Suitable for spherical roller or self aligning ball bearings of ISO dimensional series 02, 03, 22, 23 and 32

- For shaft diameters from 20mm to 160mm (Large bearing housings SNCD up to 500mm)

- Housing material: Cast iron with lamellar graphite or nodular graphite (SNCD)

Easy assembly, as split SNC housings can be separated to allow the bearings to be inserted from above.

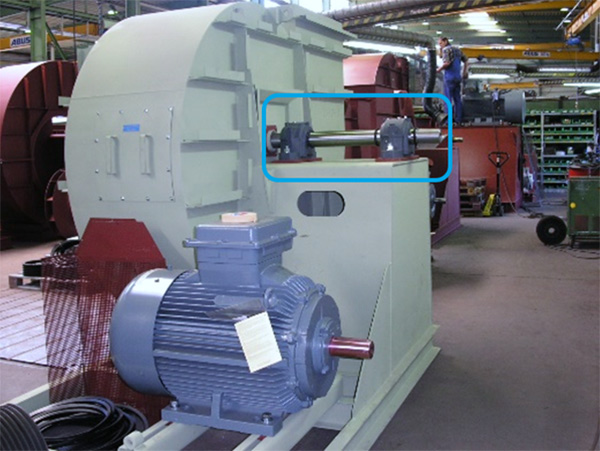

In this application example, you can see the rotor bearings in an industrial fan.

One-piece designs

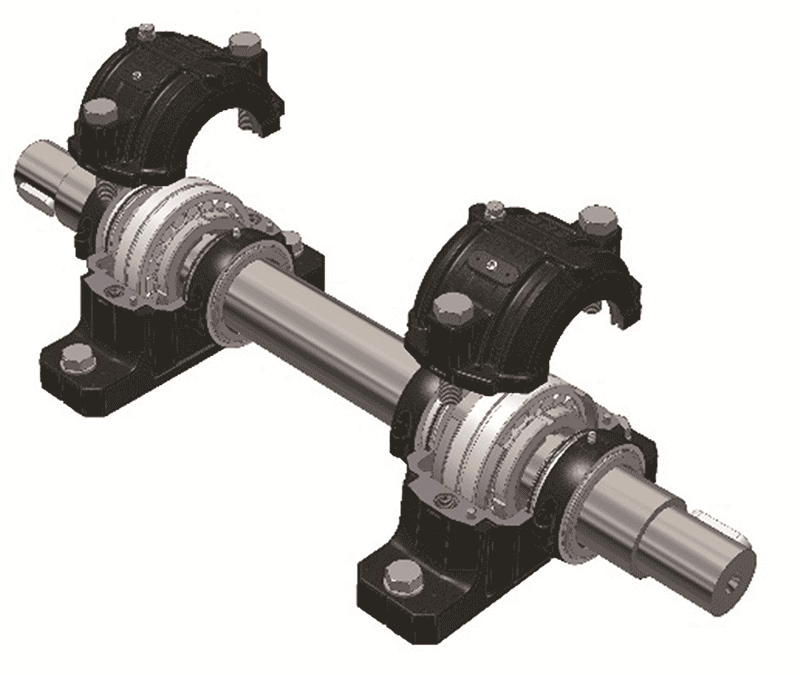

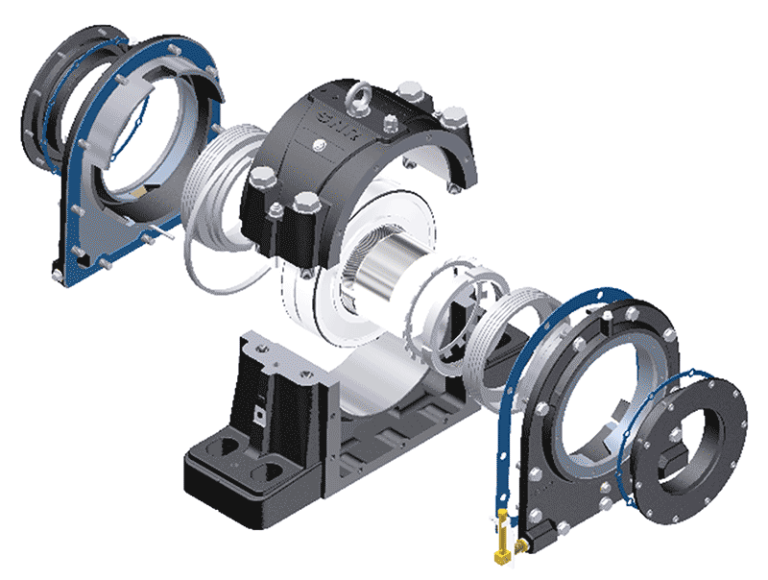

Bearing housings of this design have no split in the bearing seat surface. The bearings are mounted from the side. Flanged bearing housings and so-called block bearing housings are manufactured by SNR (a brand of NTN) in a one-piece design. Block bearing housings are suitable for the installation of two or more rolling bearings.

For example, at bearing manufacturer NTN (and its associated brands NTN and SNR), the designations for units with grease lubrication are ZLG and DLG, and units with oil lubrication are called ZLOE. These bearing housings have the shape of a tube, with the bearings arranged at an optimum distance from each other at the ends of the housing. Misalignment of the bearings is practically impossible, as the bearing seats are completely parallel. Bearing housings of this type are often used for industrial fans because they run very smoothly and can absorb large moment loads. Block bearing housings can be configured in a variety of ways by equipping them with different bearing combinations.

Features of one-piece designs:

- Aligned bearing seat positions for high shaft runout accuracy

- Usable bearing types: Deep groove ball bearings, angular contact ball bearings and cylindrical roller bearings (can be mixed within a block bearing)

- Housing material: Cast iron with lamellar graphite

- For shaft diameters from 30mm to 120mm

- Suitable for applications with high axial or radial forces – also in combination with high speeds

- High running smoothness due to axially preloaded bearings

- Preferred bearing for industrial fans

- Sealing system: Felt strip / V-ring seal

- Can be configured as pre-assembled, ready-to-use complete units

The one-piece designs can include flanged bearing housings and bearing housings for special applications, which are described in more detail below.

Due to the more compact housing design, flanged bearing housings require less installation space than plummer block housings. The housings, which are equipped with three or four mounting holes depending on size, are bolted to a machine wall. Slight mounting or shaft alignment errors are compensated for by the spherical roller or self-aligning ball bearings installed. The one-piece housings of series 722500 can be equipped with a closed end cover or with a cover for through shafts.

Features of flanged bearing housings:

- Housing material: Cast iron with lamellar graphite

- Usable bearing types: 12..K, 22..K, 222..K

- For shaft diameters from 20 mm to 100 mm

- Version with closed cover (type A) or open cover for through shaft (type B)

- Sealing system: Felt strip seal

- Regreasable

In addition to flanged bearing housings, there are also bearing housings for special applications. These include TVN housings, which are compact, one-piece bearing housings made of grey cast iron, specially developed as wheelset bearings for conveyor and hardening trolleys. For applications under normal temperature conditions, the housings can be equipped with standard deep groove ball bearings or self-aligning ball bearings. For applications in the high-temperature range, heat-stabilised high-temperature deep groove ball bearings of the F605 series from NTN can be used (maximum temperature: 350°C).

Features of high temperature bearing housings:

- Heat-stabilised bearings up to 350°C

- Special sealing

- High temperature lubricant

Bearing housings with grease or oil lubrication

Grease is the most suitable lubricant for rolling bearings in most cases, as it is usually less expensive, can be fed into the bearing enclosure with little effort and seals do not have to be designed as elaborately.

In many cases, bearing housings do not need to be regularly supplied with fresh grease. If the operating conditions are moderate, the grease is only replaced in the event of general service maintenance.

Bearing housings with oil lubrication are preferred for use in machines that are operated at high shaft speeds or where very short grease relubrication intervals are to be expected. The lubricating oil can improve heat dissipation and increase bearing operating life, by installing additional devices (such as external oil cooling). Oil bearing housings are available from SNR (a brand of NTN) as a split design (SNOE) and as a block bearing (ZLOE).

For example, labyrinth seals are used for sealing in oil bearing housings. Non-contact seals are preferable at high circumferential speeds to reduce frictional heat in the system.

Bearing housings of the SNOE series operate with oil sump lubrication. The oil is conveyed to the upper area of the bearing by a rotating oil feed ring.

The initial supply of grease. Before commissioning, the bearing and the seals as well as part of the interior are supplied with lubricant.

You may also be interested in

Fit selection

Interference fit, transition fit, clearance fit. You should know and be able to define these three types of fit after reading this article. But before

Lifetime calculation

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

Materials and manufacturing

Materials and manufacturing Have you already had a look at our chapter on structure and function? Maybe you asked yourself what rolling bearings are actually

O, X and tandem arrangement

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different

The angular contact ball bearing

The angular contact ball bearing is virtually the brother of the deep groove ball bearing. Characteristics of angular contact ball bearings Perhaps you already know

The tapered roller bearing

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the