Characteristics of cylindrical roller bearings

Do you remember the characteristic that all roller bearings have in common? We are talking about line contact, which can also be seen in cylindrical roller bearings. These bearing types are therefore suitable for supporting very high loads, especially radial loads. For this reason, cylindrical roller bearings are typically used in gearboxes of, for example, wind turbines; as wheelset bearings of rail vehicles or as non-locating bearings in electric motors.

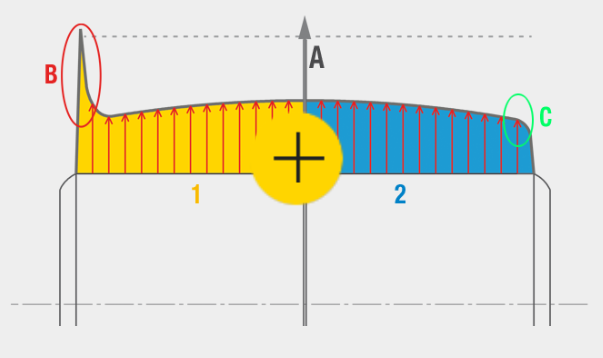

Several components of cylindrical roller bearings are profiled, including the end faces of the rolling elements, the guide ribs of the raceway and the raceway itself. The rolling elements are also logarithmically profiled. The profiling of the rolling elements ensures better lubricant distribution on the guide rib, and also optimises the surface contact pressure. A special feature is that in addition to the mandatory components, e.g. inner ring, outer ring, rolling elements and cage, which are characteristic of every rolling bearing, cylindrical roller bearings can have additional lips. The fixed lips, which are directly integrated in the inner and/or outer ring, and the loose collar rings serve to guide the rollers on one or both rings. Depending on the design of the cylindrical roller bearing, which can be chosen based on application conditions, it is quite easy to remove one of the rings from the bearing. Furthermore, the lubrication of cylindrical roller bearings is even more important compared to other bearing types because their components are subjected to high friction.

So far, so good. But what other special features do cylindrical roller bearings have? On the one hand, it is worth mentioning that they have a higher load rating for the same installation space as ball bearings or tapered roller bearings and can support higher radial loads.. In addition, despite the line contact, cylindrical roller bearings achieve the highest limiting speeds compared to many other roller bearings. As already indicated, mounting and dismounting of these bearings is generally quite uncomplicated due to the separability of the inner and outer ring. In some designs, the rollers can also slide axially on the inner or outer ring, so that cylindrical roller bearings can be used as non-locating bearings. However, individual types (NUP, NH on both sides and NF, NJ on one side) are also suitable for supporting low axial loads. Full complement cylindrical roller bearings, (bearings without a cage), offer the advantage that more rolling elements are installed in the same space and the load rating is therefore increased.

A disadvantage in direct comparison with ball bearings is that cylindrical roller bearings have lower limiting speeds due to the line contact of the rolling elements. Furthermore, cylindrical roller bearings are significantly more sensitive to shaft deflection than ball bearings, so misalignment should be avoided with these bearing types. In full complement cylindrical roller bearings, higher friction occurs because the rolling elements are in direct contact with each other and therefore rub against each other at high speed. In order to keep the heat generation due to friction low, sufficient lubrication is necessary. With oil lubrication, heat can be further dissipated through the oil flow.

Basically, the designation of cylindrical roller bearings starts with the letter N. Types NU and N are typically used as non-locating bearings and are not suitable for axial loads, as they only have ribs on one bearing ring. Cylindrical roller bearings with the designations NJ and NF can support axial loads from one direction and types NUP and NH are even suitable for axial loads from both directions. However, the axial load should be kept low, otherwise the rollers will generate excessive contact pressure with the lips. These types can then be used as fixed bearings for the shaft.

| Type | Properties | |

| NU | Two lips on the outer ring; outer ring, rollers and cage can be separated from the inner ring. | |

| N | Two lips on the inner ring; inner ring, rollers and cage can be separated from the outer ring. | |

| NJ | Two lips on the outer ring, one lip on the inner ring. | |

| NF | One lip on the outer ring, two lips on the inner ring. | |

| NUP | Two lips on the outer ring, one lip on the inner ring; a loose flanged ring on the rib-free side of the inner ring, which can be removed. | |

| NH | Similar to the NJ version, but has an enclosed angle ring; the angle ring can be removed. | |

Here you can see cylindrical roller bearing types and their most important characteristics at a glance.

NTN cylindrical roller bearings can be combined with the three usual types of cage. Whether a plastic, sheet steel or solid cage is ultimately fitted in a bearing depends, as usual, on the bearing series and size as well as the application conditions.

| Bearing series | Plastic cage | Pressed steel cage | Solid brass cage |

| NU10, NJ10, NUP10, N10 | —– | —– | 1005-10/500 |

| NU2, NJ2, NUP2, N2, NF2, NU2E | 204E-218E | 208*-230 | 232-264 |

| NU22, NJ22, NUP22, N22, NU22E | 2204E-2218E | 2208*-2230 | 2232-2264 |

| NU3, NJ3, NUP3, N3, NF3, NU3E | 304E-314E | 308*-324 | 326-356 |

| NU23, NJ23, NUP23, N23, NU23E | 2304E-2311E | 2308*-2320 | 2322-2356 |

| NU4, NJ4, NUP4, N4, NF4 | —– | 405-416 | 417-430 |

Here it becomes clear that none of the bearing types at NTN can be assigned exclusively to one cage material.

Ultage cylindrical roller bearings

Have you ever heard of the Ultage series? Ultage bearings from NTN are a further development of standard bearings, for example cylindrical roller bearings. These not only have larger rolling elements and a generally optimised roller profile, but also profiled raceway surfaces. Due to this profiling, bearings of this series are characterised by larger permissible misalignments than the original cylindrical roller bearings. These features mean that the service life, dynamic load carrying capacity and also the limiting speeds are higher compared to the standard bearings.

Multi-row cylindrical roller bearings

As with various other types of rolling bearings, there are special types of cylindrical roller bearings. Just like angular contact ball bearings, cylindrical roller bearings can be used in double rows to increase the load capacity. It makes sense to use them in applications where a reduced cross-sectional area is required. But that’s not all: it is possible to directly line up four of these bearings. Four-row cylindrical roller bearings are predominantly used as roller journal bearings because of their maximum load carrying capacity.

You may also be interested in

Fixed and floating bearings

Do I choose a fixed bearing arrangement, an adjusted bearing arrangement or a floating bearing arrangement? This question is important when designing a shaft system.

Lifetime calculation

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

Lubrication

Nothing works without lubrication: Every bearing runs with grease or oil lubrication, which is the basic prerequisite for avoiding metallic contact of the bearing components,

Point and line contact

What is meant by “point and line contact”? You may have already heard that rolling bearings can be split into two types. The classification depends

Rolling bearing types overview

If you have read our article on rolling bearing basics, you probably already know that rolling bearings can basically be divided into two types –

Structure and function

Components of rolling bearings The basics of rolling bearing technology include the structure and function of rolling bearings. To get you started slowly, you will