Characteristics of angular contact ball bearings

Perhaps you already know some characteristics of the deep groove ball bearing. This will be helpful in this text, because the angular contact ball bearing is very similar to the deep groove ball bearing in terms of its structure. Nevertheless, there are a few crucial differences. Angular contact ball bearings can also be used universally in many applications and are sometimes installed specifically in machine tools.

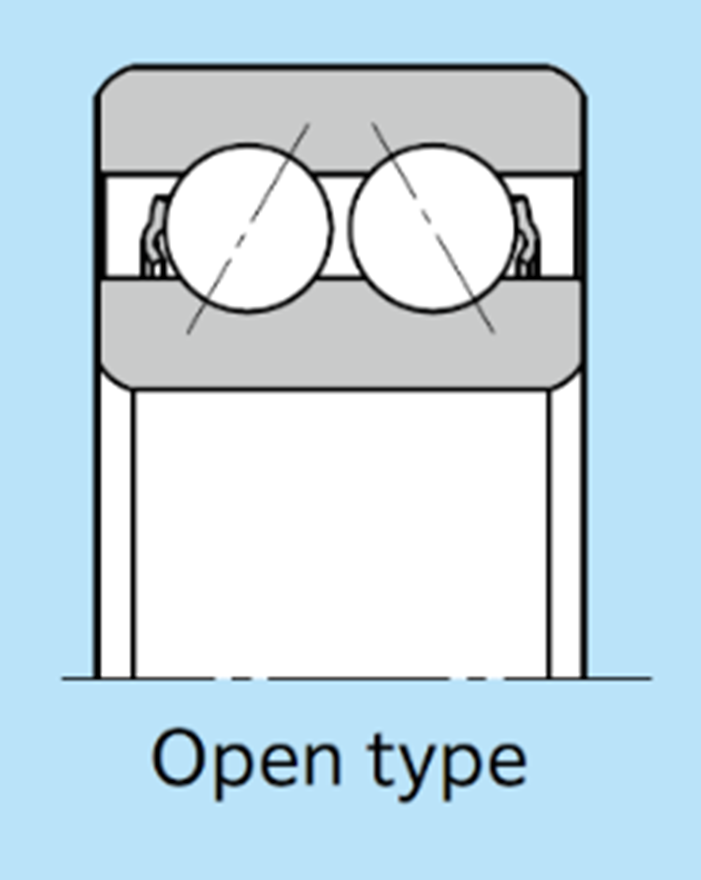

Just like deep groove ball bearings, angular contact ball bearings cannot usually be dismantled. They have a defined contact angle α, which is relative to the radial plane and represents a connecting line between the contact points on the inner ring, on the ball and on the outer ring.

Angular contact ball bearings can support radial loads as well as axial loads from one direction. Depending on the ratio of axial and radial loads, angular contact ball bearings with different contact angles are used. With regard to axial forces, angular contact ball bearings are therefore also more robust than, for example, a deep groove ball bearing. Two angular contact ball bearings are often paired with each other, which results in two rows of rolling elements next to each other. As a result, axial forces acting on the bearings can run in two different directions (O or X arrangement) or a greater load can be supported in one axial direction (tandem arrangement). In addition, angular contact ball bearings may be preloaded so that there is little or no bearing play . The advantage of preloading is that angular contact ball bearings can thus be adapted to the application in terms of bearing rigidity, shaft guidance and concentricity.

The fact that axial loads can only be absorbed in one direction, can be more of a curse than a blessing, as it is imperative to pay attention to the mounting direction when mounting individual angular contact ball bearings. However, if it is clear that axial forces can occur in both directions, the use of paired angular contact ball bearings is indispensable. Similar to deep groove ball bearings, angular contact ball bearings can also have a seal. Due to the paired installation, the mounting of angular contact ball bearings is more complicated than with deep groove ball bearings. In addition, the costs are higher if two bearings have to be installed.

According to the standard, single-row angular contact ball bearings are marked with the code number 7 and double-row angular contact ball bearings with 3 or 5. Cages for angular contact ball bearings are basically available in the three common materials: plastic, sheet steel and brass. The cage material used can be adapted according to the application. For smaller sizes, a plastic or sheet steel cage is often used for cost reasons.

| Type | Bearing series | Plastic cage | Sheet steel cage | Solid brass cage |

| Standard | 79 70 72 73 72B 73B | 7904-7913 7000-7222 —– —– —– —– | —– —– 7200-7222 7300-7322 7200B-7222B 7300B-7322B | 7914-7960 7026-7040 7224-7240 7324-7340 7224B-7224B 7324B-7340B |

| Double row | 52 53 | —– —– | 5200S-5317S 5300S-5314S | —– |

| 4-point contact | QJ2 QJ3 | —– —– | —– —– | QJ208-QJ224 QJ306-QJ324 |

Merrily mixed: some NTN bearing series come as standard with plastic cages, some with sheet steel cages and others with solid brass cages.

Angular contact ball bearing pairing

As mentioned before, angular contact ball bearings can be paired. It is possible to install the rolling elements into different arrangements. The most common arrangements of the bearings are the O, X and tandem arrangement. Especially in machine tools, bearings can also be arranged in multiple combinations of more than two.

Other angular contact ball bearing types: Spindle bearings and four point contact bearings

In addition to single and double row angular contact ball bearings, there are other types. These include, for example, spindle bearings or four-point contact bearings. Spindle bearings are manufactured in better tolerance classes than standard angular contact ball bearings and have smaller rolling elements. These are useful for achieving very high speeds. What is special about four-point contact bearings is that they can be loaded axially from any direction.

You may also be interested in

Bearing clearance, operating clearance and preload

Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do

Lubrication

Nothing works without lubrication: Every bearing runs with grease or oil lubrication, which is the basic prerequisite for avoiding metallic contact of the bearing components,

O, X and tandem arrangement

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different

Point and line contact

What is meant by “point and line contact”? You may have already heard that rolling bearings can be split into two types. The classification depends

Rolling bearing types overview

If you have read our article on rolling bearing basics, you probably already know that rolling bearings can basically be divided into two types –

Structure and function

Components of rolling bearings The basics of rolling bearing technology include the structure and function of rolling bearings. To get you started slowly, you will