Do I choose a fixed bearing arrangement, an adjusted bearing arrangement or a floating bearing arrangement? This question is important when designing a shaft system. The three variants naturally have their advantages and disadvantages.

Definition of fixed/floating bearing arrangement

First of all, it is important to know that shafts or axles are basically supported by at least one pair of bearings in the axial as well as in the radial direction. The bearing that is to prevent axial movement of the shaft in relation to the housing is called a fixed or locating bearing. For this purpose, the bearing must always be secured axially on the shaft and in the housing using suitable abutments. This axial securing can sometimes be done by means of a locknut or circlip.

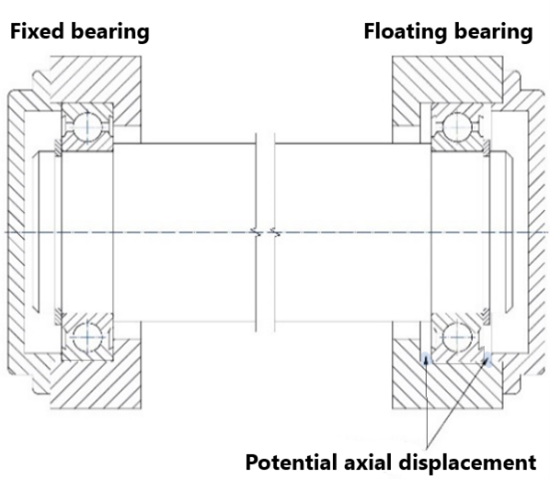

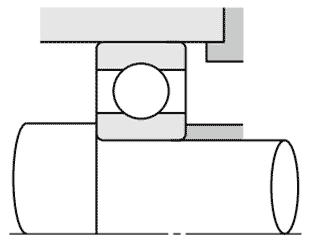

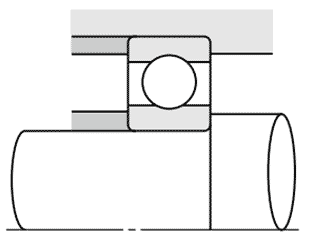

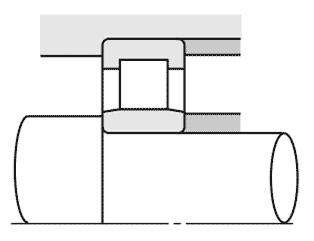

In order to compensate for thermal expansion and manufacturing tolerances, another bearing, a so-called floating bearing, is required. As can be seen in the illustration of the fixed and floating bearing, the axial displacement occurs in the housing. However, this axial displacement can also be made possible on the shaft or within the bearing itself (for example in the case of a cylindrical roller bearing of the NU or N design). In each case, the axial securing takes place on the shaft or in the housing. In the case of a cylindrical roller bearing (NU or N design from NTN), where the axial displacement occurs within the bearing, both the inner ring and the outer ring are axially secured.

| Bearing arrangement (differentiation between fixed and floating bearing side) | |||

|---|---|---|---|

| Arrangement | Comment | Application examples | |

| Fixed bearing side | Floating bearing side | ||

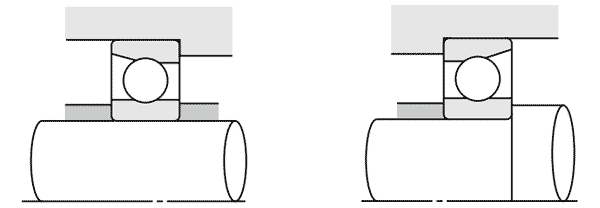

|  |

|

|

|  |

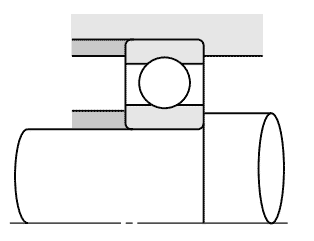

|

|

Here you will find a general overview of fixed and floating bearing arrangements

The adjusted bearing arrangement

In addition to the fixed and floating bearing arrangement, there is also the adjusted bearing arrangement. Adjustment means that the rings of two bearings are displaced until either the desired preload or the desired clearance is achieved. This results in more accurate guidance and higher bearing stiffness. Tapered roller bearings and angular contact ball bearings are mainly used for this “adjustment“, but many other rolling bearing types (such as deep groove ball bearings) are also suitable for an adjusted bearing arrangement. In order to align two bearings against each other, there are three possible bearing arrangements: The O, X and tandem arrangement. The table shows the O and X arrangements.

| Bearing arrangement (adjusted bearings) | ||

| Arrangement | Comment | Application examples |

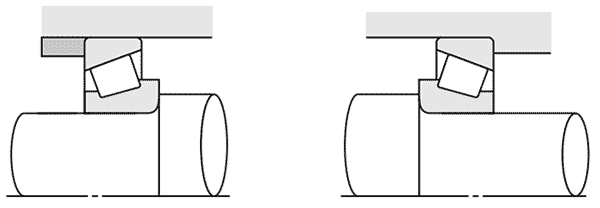

O-arrangement (Back to Back) |

|

|

X-arrangement (Face to Face) |

|

|

You can find more information on the O and X arrangement here.

However, it has to be taken into account that adjusted bearings also have disadvantages. For the “adjustment“, considerably more time is needed during assembly than for a fixed/floating bearing. The reason for this is, for example, the setting of a defined clearance or preload.

The fully floating bearing arrangement

Another bearing arrangement that essentially has a lot in common with the adjusted bearing arrangement is the fully floating bearing arrangement. In contrast to the adjusted bearing, this always involves some axial play, which is why there is no precise axial guidance with the floating bearing. The amount of axial clearance s is predetermined by the designer in the case of a floating bearing arrangement, so that the bearings are not subjected to axial distortion under any circumstances. A floating bearing arrangement is chosen for gearboxes, for example, if the gearing requires a free axial position or the axial guidance accuracy does not have to be particularly high.

Angular contact ball bearings and tapered roller bearings, both of which must be adjusted, are conversely unsuitable for the fully floating bearing arrangement. The most prevalent rolling bearing types that are suitable for a floating bearing arrangement are summarised in the list.

In addition to the three bearings, other rolling bearing types can of course also be used to create a fully floating bearing arrangement.

You may also be interested in

Bearing clearance, operating clearance and preload

Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do

Bearing mounting and the design of surrounding components

Generally speaking, a bearing is only as good as its environment. Who can perform at their best if they don’t feel comfortable in their surroundings?

O, X and tandem arrangement

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different

The angular contact ball bearing

The angular contact ball bearing is virtually the brother of the deep groove ball bearing. Characteristics of angular contact ball bearings Perhaps you already know

The cylindrical roller bearing

Characteristics of cylindrical roller bearings Do you remember the characteristic that all roller bearings have in common? We are talking about line contact, which can

The tapered roller bearing

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the