Characteristics of bearing inserts

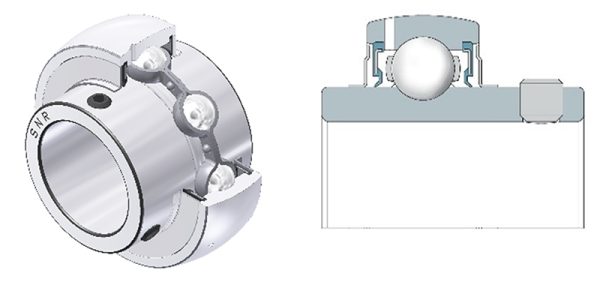

The bearing insert, which in principle is constructed like a deep groove ball bearing, has a spherical outer ring surface. The seat in the housing, on the other hand, is a spherical recess and enables the bearing insert to be held securely without the need for further fastening elements. This configuration allows the bearing to absorb loads in the radial and axial directions and to compensate for slight shaft misalignments.

Due to their user-friendliness and cost-effectiveness, bearing units can be found in many industrial sectors. These include, among others, agricultural machinery, woodworking and packaging machines, equipment in the food industry as well as in conveyor technology.

Soil preparation machines are equipped with bearing units. Dust, moisture, chemicals and impacts from the solid soil layers are some of the conditions that must be withstood here.

Bearing units can also be found in a car wash.

Bearing units are frequently used for machining processes in the food industry, for example for conveyor belts.

Bearing units are self-aligning and can compensate for shaft misalignment.

In contrast to deep groove ball bearings, bearing inserts generally have a seal. They are pre-greased and in most cases can be re-greased via a lubricant feed in the housing. An integrated clamping system on the inner ring allows easy mounting on cylindrical shafts.

In terms of housing designs, a distinction is made between pillow block housings, flanged housings and take-up housings (from left to right).

The assembly and disassembly of the units can be carried out without special prior knowledge and special assembly tools.

There are various methods available for mounting a bearing insert on cylindrical shafts. The most suitable fastening system is determined by the application. From a design point of view, the maximum permissible speed, the direction of rotation of the shaft and the running behaviour as well as the effect of axial loads must be taken into account. Furthermore, economic aspects, the available installation space and the ease of installation can be decisive for the choice of fastening system.

Bearing units can be mounted on drawn shafts because the bore is always 0+ tolerance (larger than the nominal diameter of the shaft). Special machining of the shaft surface is therefore not necessary.

A wide range of plummer block and flanged bearing units as well as take-up units are available for the most diverse installation situations. Construction elements, such as clamping frames and protective caps, provide further application possibilities.

The selection of the right material also plays an important role in the reliable operation of a bearing unit. NTN’s portfolio includes bearing units with housings made of steel, spheroidal graphite cast (ductile) iron, grey cast iron, pressed steel, stainless steel and thermoplastic. Due to the very high variance of different designs and materials, bearing solutions can be achieved for many industrial applications.

The simple assembly of the units does not require any special prior knowledge on the part of the fitter. However, the operating conditions and mounting instructions must be observed. When planning, the loads, speeds and operating temperatures for the respective application must be considered, almost like any other bearing calculation. Furthermore, the consideration of sealing and the type of lubricant should play a role in the design of the bearing configuration. In practice, rolling bearings with ball type rolling elements are almost exclusively used for bearing units. The bearing geometry is identical to that of deep groove ball bearings of series 62 and 63. The limiting speed of bearing inserts is lower than that of comparable deep groove ball bearings due to the special mounting method on the shaft.

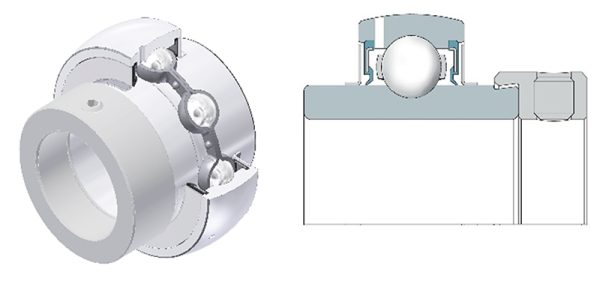

In the pictures you can see examples of the different series: The most commonly used series made of grey cast iron (top left) , the light series with housings made of pressed steel (top right), bearing units made of stainless steel (bottom left) and thermoplastic bearing units (bottom right), which are mainly used for industrial food production.

Bearing unit fixing methods

For mounting a standard deep groove ball bearing on a shaft, the inner ring is usually heated by means of an induction heating device for warm mounting. Special mounting tools are used for cold mounting. In both cases, mounting is significantly more complex and costly than for bearing inserts with an integrated mounting system.

You can find out which NTN systems are available and how they work here:

Fastening of housing bearings with:

• Set screw

• Eccentric collar

• Adapter sleeve

• Press fit

• Floating bearing screw

More detailed information on most of the listed fastening options can be found here.

The simplest and most economical mounting method is bearing inserts with set screws. The inner ring is equipped with two set screws offset by 120°. By tightening the two hexagon socket screws, the bearing inner ring is fixed to the shaft and locates the bearing unit. The recommended tightening torque must be observed when tightening the set screws. A normal Allen key is sufficient as a tool. With this method, the axis of the bearing insert is offset slightly from the centre of the shaft axis. This slight offset can lead to vibrations at higher shaft speeds, but is not relevant for applications with normal speeds. In contrast to bearing inserts with an eccentric collar, the bearings with set screws are also suitable for alternating directions of shaft rotation.

Bearing inserts with set screws are suitable for both directions of rotation.

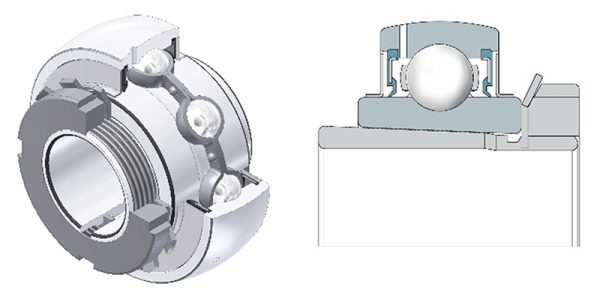

The mounting method using an eccentric collar is also very common in industrial machines. With this fastening method, the bearing insert is mounted together with an eccentric collar. The eccentrically machined collar on the inner ring and the eccentric recess on the eccentric collar are clamped together during mounting and ensure the fixation of the bearing on the shaft. The eccentric collar must be fixed in the direction of rotation of the shaft and finally secured with a set screw. This type of mounting is not suitable for quick changes in the direction of rotation, as the eccentric collar could come loose during alternating operation. The larger installation space required by the additional component must also be taken into account.

You can see the eccentric collar on the left and right side of these pictures.

Just like spherical roller bearings, bearing inserts can also have a tapered bore. However, these are usually mounted on a cylindrical shaft by means of an adapter sleeve. Adapter sleeve mountings generally represent a very secure shaft connection. During mounting, the bearing is pushed onto the sleeve until the recommended reduction in radial internal clearance is achieved. Setting the correct internal clearance value is crucial for the service life of the bearing. The bearing is secured in this position with a lockwasher and locknut.

Shaft mounting with an adapter sleeve is somewhat more complex and must be carried out professionally. Due to the number of additional components, bearing inserts with adapter sleeves are also somewhat more cost-intensive. However, with this mounting method you benefit from a very high clamp force, low-vibration running and higher speeds.

Bearing inserts with a tapered bore are typically mounted with an adapter sleeve.

Non-locating (floating) bearing

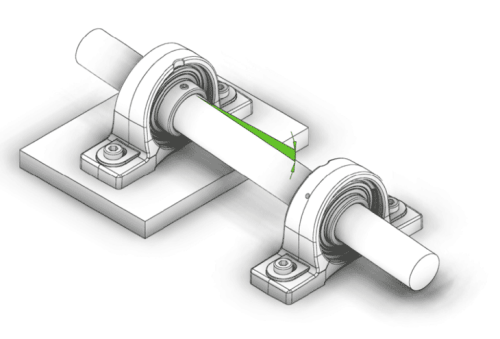

Bearing arrangements that can compensate for heat-related changes in the length of shafts are referred to as non-locating (floating) bearings. In order to avoid bearing failures due to axial tension, the shaft must be supported via a locating and non-locating bearing.

While the locating bearing side can absorb forces in radial and axial directions, the shaft on the non-locating bearing side remains displaceable – but absorbs forces only from the radial load direction. Bearing inserts from SNR (an NTN brand) with set screws, for example, can be easily converted for use as non-locating bearings.

Despite the similar term, bearing units are not to be confused with bearing housings, about which information can also be found on bearingwizard.co.uk.

By changing the set screws, a fixed bearing unit can be converted into a floating bearing unit.

You may also be interested in

Lubrication

Nothing works without lubrication: Every bearing runs with grease or oil lubrication, which is the basic prerequisite for avoiding metallic contact of the bearing components,

Point and line contact

What is meant by “point and line contact”? You may have already heard that rolling bearings can be split into two types. The classification depends

Rolling bearing types overview

If you have read our article on rolling bearing basics, you probably already know that rolling bearings can basically be divided into two types –

Sealing

During the design of a bearing assembly, the topic of sealing will always accompany you. In the following material, we will cover both integrated and

Structure and function

Components of rolling bearings The basics of rolling bearing technology include the structure and function of rolling bearings. To get you started slowly, you will

The deep groove ball bearing

Characteristics of deep groove ball bearings In its current form, the deep groove ball bearing has existed – subject to some optimisation – for about