Interference fit, transition fit, clearance fit. You should know and be able to define these three types of fit after reading this article. But before that, it is useful to understand what fitting is and what you have to consider.

Why is the choice of fit important?

It is wise to select a fit before calculating the bearing clearance, as the fit choice has a direct effect on it. Understanding this is an important aspect of mechanical engineering. The choice of fit, also called bearing fit, is very important in order to prevent or enable relative movements between the inner ring and shaft or outer ring and housing during operation.

If the interference is too small, unwanted relative movements potentially occur between the mating surfaces of the bearing and the shaft or housing. These movements can occur in a radial, circumferential or axial direction. These relative movements can cause damage to the shaft, housing and bearing, which then leads to expensive or complex repair measures. In addition to the bearing itself, the shaft and housing may also have to be replaced. There are cases, however, where the bearing should move freely, for example in the case of non-locating bearings. In this case, it must be ensured that there is sufficient clearance between the mating surfaces of the bearing and the shaft or housing. If there is no clearance, there is a risk that the bearing will jam in the event of temperature fluctuations with accompanying longitudinal expansion of the housing and/or the shaft.

With regard to the choice of fit, it should be noted that some bearings with line contact (roller bearings) can potentially also run directly in the housing and/or on the shaft. The bearing fit is also very important in such cases, as it has a direct influence on the bearing clearance.

Correct fit selection is imperative. Particular attention must be paid to the geometric shape of the shaft and housing bearing seats, because all geometric errors can be transferred to the inner ring and outer ring. They can lead to vibrations, noise during operation and ultimately to bearing damage (see list “Bearing damage due to incorrect fit”). To avoid this, it makes sense to choose an interference, transition or clearance fit only after careful analysis of the operating conditions (and the surrounding components). In doing so, one should strictly adhere to the recommendations of the rolling bearing manufacturer according to the catalogue.

Bearing damage due to incorrect fit

- Cracks in the ring, early flaking and misalignment of the raceway

- Abrasion on the ring and shaft or housing due to creep and fretting-corrosion

- Seizure caused by excessive negative bearing clearance (preload)

- Noise generation and loss of concentricity as a result of raceway deformation

Types of bearing damage from incorrect fits are many and varied, but fortunately also avoidable.

Important criteria for consideration are the shaft and housing material, the wall thickness and the surface finish. In addition, there are the operating conditions of the rolling bearing – these include factors such as the load type, size and direction, the speed and temperature.

Interference fit

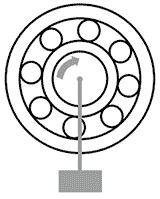

In general, interference fit is an effective method of fixing the mating surface of the bearing rings with shaft or housing. As the illustration for “Radial load and bearing seat” shows, an interference fit is required for bearing rings with rotating loads – this applies to both the inner ring and the outer ring. “Bearing rings with rotating loads” refers to bearing rings that are subjected to rotating loads relative to their radial direction. Strong interference fits are also recommended for operating conditions with high vibration or shock loads, for hollow shafts and thin-walled housings, as well as for applications with housings made of plastic. Furthermore, fits with low interference are sometimes recommended for applications with high running accuracy requirements or when using small or thin-walled bearings. In most cases, the bearing must be pressed onto the shaft or into the housing in the case of an interference fit, which is why mounting and dismounting can be quite time-consuming. The prerequisite is that the shaft is slightly larger than the inside diameter d of the inner ring of the rolling bearing. Another general disadvantage of the interference fit is the reduction of the bearing clearance or operating clearance.

Transition fit

In addition to the interference fit, there is also the transition fit, which is used when there are tolerances ranges in an application that allow for both a clearance as well as an interference.

Clearance fit

For non-separable bearings, such as deep groove ball bearings, a clearance fit is recommended for either the inner ring or the outer ring. In this case, the bearing ring that is subjected to a point load is provided with a loose fit. The outside diameter D of the bearing outer ring is smaller than the minimum inside diameter of the bearing housing seat; or the inner ring inside diameter d is larger than the maximum shaft outside diameter. The relationship between the bearing seat and the type of load is shown in the next table.

| Load type | Bearing rotation | Ring load | Bearing seat |

Fixed load

|

Inner ring rotates Outer ring static | Circumferential or rotating load for the inner ring Point or static load for the outer ring | Inner ring: Tight fit Outer ring: Loose fit |

Rotating load

|

Inner ring static Outer ring rotates | ||

Fixed load

|

Inner ring static Outer ring rotates | Point or static load for the inner ring Circumferential or rotating load for the outer ring | Inner ring: Loose fit Outer ring: Tight fit |

Rotating load

|

Inner ring rotates Outer ring static |

Radial load and bearing seat: Here you can see the connection between the load type and bearing fit.

Determination of the bearing fit

The interference can be determined on the basis of the diameter tolerances of the shaft and housing bores and the tolerances of the bearing rings. Recommended values for the interference and possible fits for various applications can usually be found in corresponding tables, for example in the NTN catalogue.

Minimum and maximum interference

In some applications it is necessary to calculate a minimum and maximum interference between inner ring and shaft or outer ring and housing. With regard to minimum interference, the following factors should be considered:

Reduction of the interference due to:

- Radial loads

- Differences between operating temperature and ambient temperature

- Change of shape/surface of the mating surfaces

- Deformation

Inner and outer ring tension must be taken into account when selecting fits.

The first factor considered in detail is therefore the fact that the interference between the inner ring and shaft is reduced when a radial load acts on the rolling bearing. This influence, which will be referred to below as the required effective interference corresponding to the radial load ∆dF can be calculated using formula 7 and formula 8.

Formula 7

Fr ≤ 0.3 Cor

∆dF = 0.08 (d x Fr /B)1/2 N

Formula 8

Fr > 0.3 Cor

∆dF = 0.02 (Fr /B) N

The formulas are used to calculate the reduction of interference due to radial load △dF.

∆dF = Required effective interference relative to radial load μm

d = Bearing bore diameter, mm

B = Inner ring width, mm

Fr = Actual radial load, N

Cor = Basic static load rating, N

A handful of variables are used for the calculation of ∆dF.

The interference between inner rings and steel shafts is reduced by temperature increases (difference between bearing temperature and the ambient temperature, ∆T) due to bearing operation. The calculation of the minimum required interference in such cases is shown in formula 9.

Formula 9

∆dT = 0.0015 × d × ∆T

∆dT = Required effective interference for the temperature difference in μm

∆T = Difference between bearing inner ring temperature and the ambient temperature in °C

d = Diameter of the bearing bore in mm

∆dT is calculated with this formula.

Furthermore, when selecting the fit, it must be taken into account that the fitting surface may be smoothed as a result of press fitting – in contrast to heat fitting. This also means that the interference is reduced. The extent to which the interference decreases depends on the roughness of the mating surfaces. In general, a reduction of the interference must be expected (see “Reduction of the interference“).

Reduction of the interference:

• For ground shafts: 1.0~2.5 μ m

• For turned shafts: 5.0~7.0 μ m

How much the interference reduces depends on the type of machining used.

The previous criteria referred to the minimum interference, but now an aspect is added that concerns the maximum. The use of bearing rings with interference leads to tensile stresses and compressive stresses on the mating surfaces. If the interference is too large – the specified upper limit of approx. 127 MPa must always be observed – one should not be surprised about damage to the bearing rings and the subsequent reduced service life. The consequences of excessive interference can be cracks in the inner ring and breakage of the guide ribs.

Fit selection for materials with high thermal expansion

Shafts and housings can be made of materials other than steel. Particularly in the case of materials with high coefficients of thermal expansion (e.g. aluminium), it must be taken into account that the fit of inner ring and shaft or outer ring and housing changes when the temperature rises during operation of the bearing. Because materials such as aluminium expand faster than steel, for example, this can only be compensated for to a limited extent by tighter fit for alloy housing. If the temperature fluctuations are too extreme, the housing should be made of materials with comparable expansion coefficients such as cast steel.

Formula 10

∆dTE = (∝1-∝2) × d × ∆T

∆dTE = Change in interference due to different expansion coefficients, mm

∝1 = Coefficient of expansion of the rolling bearing, 1/℃

∝2 = Expansion coefficient of the shaft or housing, 1/℃

d = Reference diameter of the relevant fit, mm

∆T = Temperature difference between ambient and operation

Coefficients of expansion of individual materials must be taken into account when choosing the fit. The reason for this is that materials other than steel have different coefficients of expansion.

You may also be interested in

Bearing clearance, operating clearance and preload

Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do

Lifetime calculation

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

The spherical roller bearing

Characteristics of spherical roller bearings Spherical roller bearings are real all-rounders. They are able to support heavy loads in both axial and radial directions. Spherical