Components of rolling bearings

The basics of rolling bearing technology include the structure and function of rolling bearings. To get you started slowly, you will learn everything about the essential components before we explain how they are arranged and function within the rolling bearing. Letʹs go!

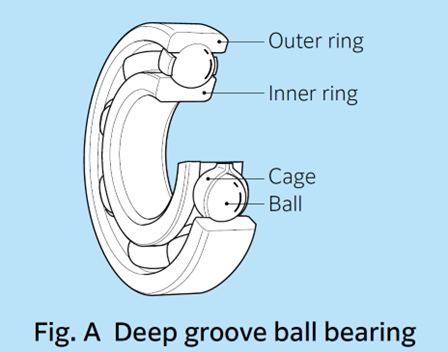

In total, there are four main components: Rolling bearings consist of an inner ring, outer ring, rolling elements and a cage. The inner ring is usually mounted on an axle or shaft and the outer ring in a housing. Optionally, a seal can be installed in a groove on the inner and outer ring. On the outside of the inner ring as well as on the inside of the outer ring lies the bearing raceway. The rolling elements move along the raceway surface, and are manufactured in ball or roller form, depending on the bearing type. The rolling elements serve to ensure that the inner and outer rings can move with minimum friction. To minimise friction and protect against wear, the bearing raceways must be sufficiently lubricated with grease or oil. Between the inner and outer ring there is also a cage, whose function is to separate the rolling elements. It should also position the rolling elements around the circumference of the rings and guide them. Cages can be made of different materials, so a distinction is made between sheet metal, solid metal or plastic cages.

Axial- and radial bearing

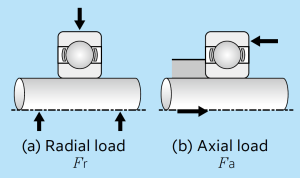

Depending on the direction of the load to be transmitted (the contact angle), a distinction is made between axial and radial bearings. With axial load, the force acting on the rolling bearing (axial bearing) runs parallel to the axis. However with a radial load, the force acts perpendicular to the axis of the rolling bearing (radial bearing). Fortunately, this is relatively easy to remember because the word “axial” comes from “axis”, whereas “radial” comes from “radius”. The contact angle α for axial bearings is between 45° and 90° whereas for radial bearings, it is between 0° and 45°. Thus, the contact angle is higher for axial bearings relative to radial bearings.

You may also be interested in

Fixed and floating bearings

Do I choose a fixed bearing arrangement, an adjusted bearing arrangement or a floating bearing arrangement? This question is important when designing a shaft system.

Materials and manufacturing

Materials and manufacturing Have you already had a look at our chapter on structure and function? Maybe you asked yourself what rolling bearings are actually

Point and line contact

What is meant by “point and line contact”? You may have already heard that rolling bearings can be split into two types. The classification depends

Rolling bearing types overview

If you have read our article on rolling bearing basics, you probably already know that rolling bearings can basically be divided into two types –

Sealing

During the design of a bearing assembly, the topic of sealing will always accompany you. In the following material, we will cover both integrated and

The spherical roller bearing

Characteristics of spherical roller bearings Spherical roller bearings are real all-rounders. They are able to support heavy loads in both axial and radial directions. Spherical