You may have already learned interesting facts about damage types such as fatigue damage or wear in our other articles. This article concerns another type of damage: Plastic deformation. Plastic deformation can be defined as permanent deformation caused by exceeding the yield point. This can usually happen in two different ways:

- Overload

- Particle indentations

Overload

An overload occurs when the Hertzian pressure in the rolling contact exceeds the permissible contact stress. Mishandling of the rolling bearing can also lead to plastic deformation (for example striking directly with a hammer during assembly). Mounting errors, which are mainly due to human error, can never be completely ruled out. In practice, it is advisable to attend a mounting training course at a rolling bearing manufacturer. There, it is explained how and with which tool a rolling bearing is best mounted. Overload can occur not only with a stationary bearing, but also during dynamic operation. A plastic deformation can occur here due to a dynamic overload (see: dynamic load rating C) or as a result of shocks.

Basic static load rating C0 and static safety factor S0

The calculation of the static safety factor S0 represents a decisive factor to prevent plastic deformations due to the operating conditions. Depending on the application, rolling bearing manufacturers such as NTN recommend certain values for the static safety factor S0. Recommendations for this can be found in the manufacturer’s catalogues). It can be calculated using the following formula.

Formula 17:

S0 = C0 / P0

Formula 2 (see also: Contribution service life calculation)

P0 = X0 x Fr + Y0 x Fa

The basic static load rating C0 can be found in the bearing dimension table in the manufacturer’s catalogue. This refers to a defined static load limit at which a certain degree of permanent deformation occurs.

The static equivalent load P0 can be calculated for radial bearings using the following formula.

S0 = Static safety factor

C0 = Basic static load rating

P0 = Static equivalent load

Particle indentations

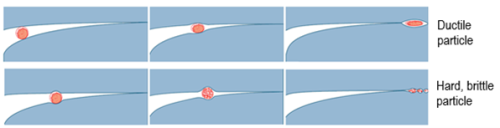

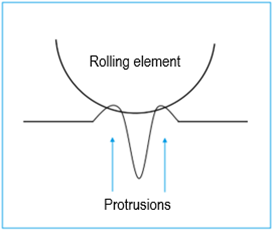

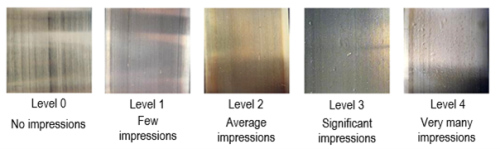

Rolling elements can roll over particles which, may have penetrated the bearing due to a lack of cleanliness or incorrect handling or have arisen from wear. Plastic deformations are found both on the raceways of the bearing rings and on the rolling elements (see illustration).

Material is displaced from the raceway by the penetration of the particles into the surface. The rolling element that follows rolls over these protrusions again. If the height of the lubricating film is not sufficient, direct contact occurs between the protrusion and the rolling elements. In addition, stress peaks occur in the protrusions. This leads to material fatigue at these points and to spalling of the protrusion. The result is fatigue damage. The whole thing can be compared more vividly with a marathon runner (the roller bearing) who has a stone (foreign particle) in their shoe. In this case, the runner would also give up early.

The size and shape of this plastic deformation depends on the type, size and hardness of the particles. A distinction is made between soft particles, particles made of hardened steel and hard, mineral particles. Examples of the three types of indentations caused by particles can be found in the table.

Type of particles | Examples |

Soft particles | Fibres, elastomers/plastics |

Hardened steel particles | From gearings or bearings |

Hard, mineral particles | Sand (silicate) |

Hard particles cause the biggest indentations compared to the other types.

Even the smallest particles in the µ range have serious effects, which is why absolute cleanliness is required when mounting and using rolling bearings. The lubricant should be stored properly and only opened before greasing. Improved sealing can also be a solution to minimise contamination in the lubricant.

You may also be interested in

Corrosion

Have you ever heard of corrosion? Corrosion is basically divided into two main forms according to ISO 15243: Corrosion by moisture and fretting corrosion. Fretting

Cracks and fractures

Cracks and fractures are not only extremely annoying, they are also one of the most common types of rolling bearing damage. The reasons for such

Electro-erosion

This article (based on ISO 15243) is all about electro-erosion – but what is it? Electro-erosion is understood to be a local structural change and

Fatigue damage

If a rolling bearing “packs up” after some time despite correct bearing selection, lubrication and handling, it is very likely to be fatigue damage. Fatigue

Sealing

During the design of a bearing assembly, the topic of sealing will always accompany you. In the following material, we will cover both integrated and

Wear

Rolling bearings, like other mechanical components, encounter problems such as wear. Wear describes the progressive removal of material from surfaces and is caused by two