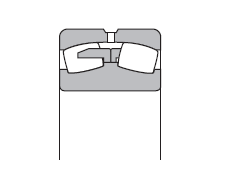

Characteristics of spherical roller bearings

Spherical roller bearings are real all-rounders. They are able to support heavy loads in both axial and radial directions. Spherical roller bearings are mainly used in heavy industrial machinery – for example in ship propellers, stone crushers or as main rotor bearings in wind turbines.

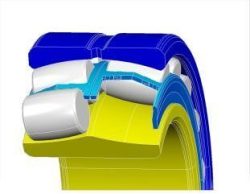

The raceways of spherical roller bearings are spherically ground, allowing the rows of rolling elements to oscillate about the axis of rotation. The rolling elements are barrel-shaped and, due to their axes being inclined relative to the axis of rotation of the bearing, can swing out and counteract a misalignment. Spherical roller bearings are completely self-aligning.

Spherical roller bearings have various advantages. On the one hand, thanks to their design, they can support a combination of radial and axial loads on both sides (combined loads). On the other hand, spherical roller bearings generally have a high load carrying capacity and are capable of withstanding shock loads. The main advantage over other rolling bearing designs is that spherical roller bearings can compensate for static and dynamic misalignments up to a maximum of 2°. Spherical roller bearings are universally applicable rolling bearings and when cost is measured against their high performance, have an optimal price-performance ratio.

After the whole series of advantages that spherical roller bearings bring with them, the question arises as to whether they also have disadvantages. Strictly speaking, there is only one aspect worth mentioning here: Spherical roller bearings capability to support purely axial loads is limited.

B type

The bearing type code number for spherical roller bearings is 2. There are also various spherical roller bearing designs, the first of which is the B design.

This is the original standard type at rolling bearing manufacturer NTN. It is characterised by asymmetrically ground rollers. Due to their geometry, the rollers are pressed against the integral centre rib, resulting in excellent kinematic rolling behaviour with low friction. The disadvantage of the B-type is a relatively lower load rating in relation to the symmetrical roller type (E-design). The B-type can be equipped with a plastic, sheet steel or solid cage and is useful for various types of applications.

E type

In addition to the B-type, E-type spherical roller bearings are also of importance and are generally characterised by a particularly high load carrying capacity. They can be subdivided again; the EA, EM, EMA and EG15 designs are worth mentioning in this context. All four have in common that they are part of the NTN Ultage series (Ultage is the premium design of various rolling bearing types at NTN). They are thus optimised E-type bearings. Furthermore, the rolling elements of all E-Type bearings have symmetrical rollers. They also have a circumferential groove and lubrication holes, so the bearing can be relubricated easily. All open spherical roller bearing designs from NTN can be used at operating temperatures of up to 200°C.

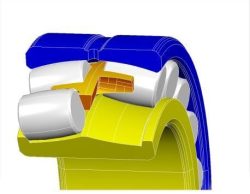

EA type

There are some differences between the various E types, which is why the individual designs are presented in more detail below, starting with the EA type. This type has a sheet steel cage with inner ring guide, which consists of two halves. The cage has special pockets that precisely guide and hold the rolling elements. The EA design is used in general applications.

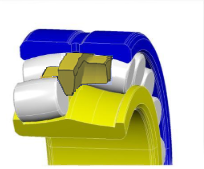

EM type

The EM type differs from the EA type in that it is equipped with a one-piece solid brass cage. This is indicated by the suffix M in the type designation. In this case, the cage is roller-guided and there are side ribs on the inner ring which serve as roller guides. The use of bearings of EM design makes sense in difficult application conditions such as high levels of shocks and vibrations.

EMA type

The EMA types have a one-piece reinforced solid brass cage. Similar to the EM type, the EMA design also has side ribs for roller guidance on the inner ring, but the cage is outer ring guided. The EMA type is used in applications where the demands on the cage are even higher than with the EM design. Designs such as the EMA design may be more expensive than EM designs due to the more complex production technology.

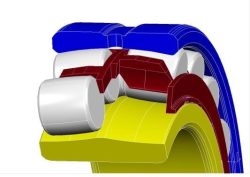

EG15 type

In a bearing of the EG15 design, a two-piece polyamide cage, which is rolling element guided, is installed as standard. The EG15 type has no conventional side ribs; instead an optimised contour is built into the cage, which serves an efficient roller guide as well as distributing lubricant more efficiently. Due to the use of plastic (polyamide) as cage material, it has a maximum operating temperature of 150°C. EG15 bearings are therefore only suitable for applications with moderate operating temperatures and are often used in applications where low noise is required.

Sealed spherical roller bearings

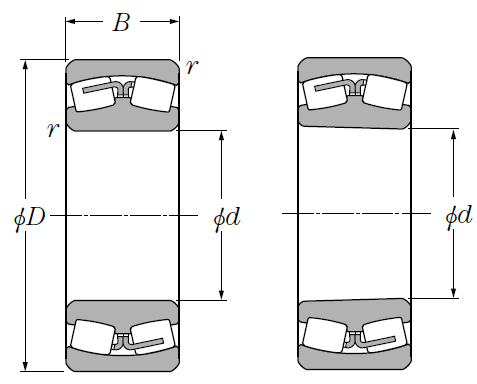

In E-Design there are also other spherical roller bearing types, for example sealed bearings. These are used in environments where there is a risk of foreign particles entering the bearing. In addition to bearings with a contact seal, NTN also offers types with metal shields, referred to as the ‘Kizei’ ® series. These are located between the inner and outer ring and are intended for use in applications with particularly coarse contamination, as there is still a small gap between the outer ring and the shield (suffix Z). The advantage of this bearing type is that they still have the standard width of an open spherical roller bearing and do not require additional installation space, unlike types with a contact seal.

A version of the E-design with contact seals (left) as well as the E-design with shields (right) are also part of the Ultage series from NTN.

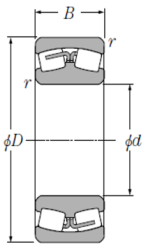

Spherical roller bearings with tapered and cylindrical bore

For spherical roller bearings, types exist with either a conical or tapered bore (suffix K) and with a cylindrical bore.

Adapter sleeves play a central role in installing spherical roller bearings with a tapered bore. An adapter sleeve is used between the shaft and the inner ring in these bearings and facilitates fitting. In this case, the bearing and the adapter sleeve can be freely positioned on the shaft before the bearing is fastened. In addition, the adapter sleeve offers the advantage that the bearing clearance can be adjusted a little with its help. Lock nuts and locking plates are also required for mounting. In addition to adapter sleeves, there are also withdrawal sleeves that are used not only for mounting but also for easier dismounting of the bearings.

The installation of a bearing with a cylindrical bore on the other hand, makes sense in applications that do not offer much space. In such cases, the bearing is heated and mounted using a suitable heating source.

You may also be interested in

Point and line contact

What is meant by “point and line contact”? You may have already heard that rolling bearings can be split into two types. The classification depends

Rolling bearing types overview

If you have read our article on rolling bearing basics, you probably already know that rolling bearings can basically be divided into two types –

Sealing

During the design of a bearing assembly, the topic of sealing will always accompany you. In the following material, we will cover both integrated and

Structure and function

Components of rolling bearings The basics of rolling bearing technology include the structure and function of rolling bearings. To get you started slowly, you will

The needle roller bearing

Characteristics of needle bearings The needle roller bearing did not get its name by chance, because its rolling elements are – surprise – characterised by

The tapered roller bearing

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the