What is a rolling bearing?

Would you like to learn more about rolling bearings? Then you’ve come to the right place. But let’s start with a short explanation: A rolling bearing is a machine component that is used in various applications. Through the rolling bearing, a movable connection of two components (shaft and housing) can be created, whereby load transmission is made possible with minimal friction. The term “rolling bearing” is the umbrella term for bearings in which rolling elements perform rolling motion and transmit a load between two opposing surfaces. The main components of a rolling bearing are the inner ring, outer ring, cage and rolling elements. Rolling elements can come in different shapes.

Rolling bearings come in a wide variety of sizes.

The rolling bearing types: Ball bearings and roller bearings

Rolling bearings can be divided into two types. In addition to ball bearings, which are probably the better-known rolling bearings, roller bearings are another type. Today, it is possible to manufacture rolling bearings in various sizes and with a wide variety of materials. As a general rule, the dimensions are standardised, but there are also special bearings tailored to specific applications.

Ball and roller bearings can be further subdivided into different types of rolling bearings. Here at wälzlagerwissen.de you will find relevant information not only on these numerous types, but also on everything else worth knowing about rolling bearings!

Application areas of rolling bearings

The functions of the rolling bearing are very important, as they are installed in all areas where something rotates. The wide range of uses extends from large wind turbines to small electric toothbrushes – rolling bearings are needed in a wide variety of applications.

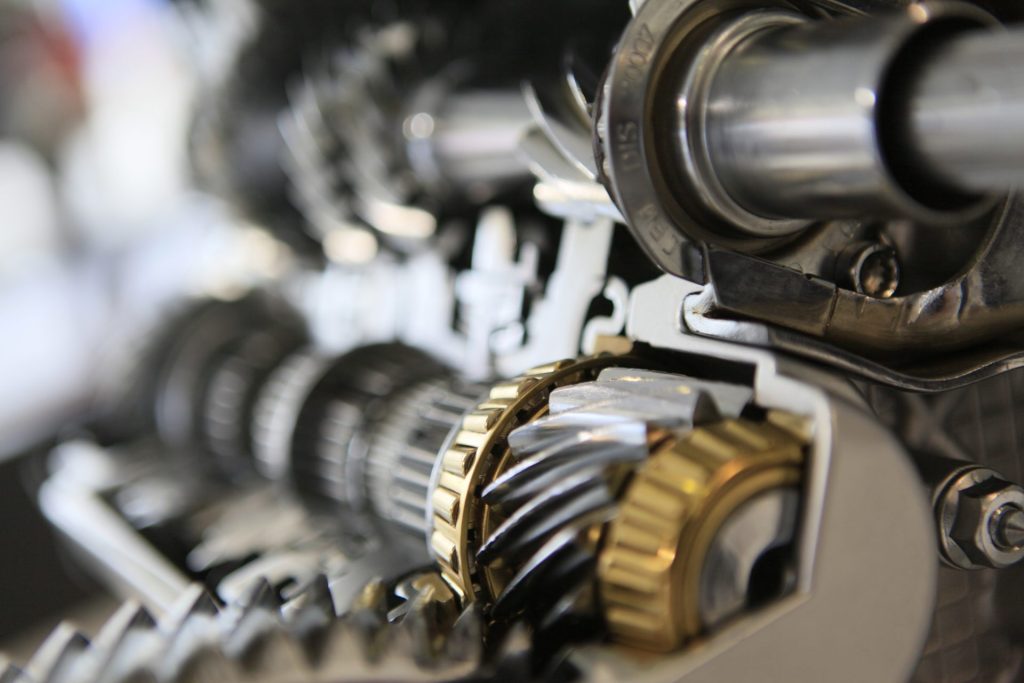

Mobility represents a diverse field of application: Rolling bearings are required in aerospace technology and the automotive market, among others. For example, they are used in aircraft engines of Airbus and Boeing planes; and in the turbines and rotors of helicopters. In addition, rolling bearings are installed in turbine pumps and satellites. In the aviation and automotive sectors, they can also be found in the chassis as wheel bearings or in gearboxes. Last but not least, rolling bearings are suitable for use in (hybrid and electric) car engines or as clutch bearings. Other areas of application are the bicycle industry and railway technology as well as agricultural and construction machinery.

As previously mentioned, rolling bearings are also indispensable in the wind energy sector. In this innovative sector, they are used, among other things, as rotor, gearbox and generator bearings. The bearings used here are primarily roller bearings such as spherical or cylindrical roller bearings.

Other industrial sectors in which rolling bearings are used are, for example, robotics and the food industry. In the former, they are in demand in the form of crossed roller bearings for precision or reduction gears for robots and in absolute sensor systems. Bearings in the food industry, on the other hand, are subject to stringent demands. Above all, they must meet the relevant health requirements so that food quality can be maintained. For this reason, a solid lubricant – and not grease or oil as is usually the case – is used here. Rolling bearings are also indispensable in industrial solutions, machine tools, textile machines, material handling, cement production and the steel industry.

As you can see, rolling bearings fulfil a central function in numerous industries and without rolling bearings many things could not be driven or moved efficiently. Rolling bearings often accompany us in everyday life without us noticing, so it’s likely that you will also have to deal with rolling bearings in your professional life.

You may also be interested in

History of rolling bearings

The origins of rolling bearings Did you know that the precursors of rolling bearings already played an important role very early on? For example, at

Lifetime calculation

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

Materials and manufacturing

Materials and manufacturing Have you already had a look at our chapter on structure and function? Maybe you asked yourself what rolling bearings are actually

Point and line contact

What is meant by “point and line contact”? You may have already heard that rolling bearings can be split into two types. The classification depends

Rolling bearing types overview

If you have read our article on rolling bearing basics, you probably already know that rolling bearings can basically be divided into two types –

Structure and function

Components of rolling bearings The basics of rolling bearing technology include the structure and function of rolling bearings. To get you started slowly, you will